It's been way too long since I blogged, and a few of you let me know that!

I'm thick in the middle of a ton of work, but even more grueling - taking care of business stuff. When you're in business, more than half of your time is taken up by paperwork, dealing with purchases and suppliers, taxes, inventory, maintenance and more. I'm not complaining, but it tends to take more time than the actual woodworking.

But the good news is - I'm back to a better balance of building more, and pushing fewer papers around my desk. Yay for that.

We started a mallet making class, and the inspiration for this a 1992 article in ShopNotes, featuring a simple and effective plan for making one.

It's a very simple project, but there are so many ways to personalize it, that this doesn't turn into a clone of someone else's mallet. The combinations of wood are endless, and after making one or two, I suspect that everyone will be making another one!

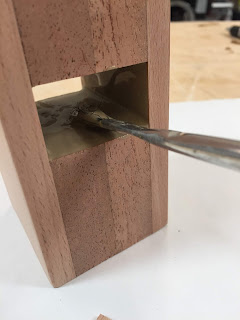

I made a second one, even heavier than the first; here's the tenon end with two slots for wedging the handle into the head.

This test fit helps, you don't want to start spreading glue and find out that you need to shave a little more wood down.

A little glue,

and some wedges draw everything tight.

When these are tapped down, the handle is secured tightly in the mortise.

After the glue sets up,

they're trimmed off, and everything gets sanded.

This is really a terrific project, and a little addicting. Like I said - once I made one, I wanted to make a ton, with different wood combinations, sizes, and weights.

In fact, I was thinking that this would be a fun little business to start - custom mallets. The next thing I knew - the most recent newsletter from Highland Woodworking came out and it featured a woman doing just that!

Want to make your own? Check out this video, which uses the same ShopNotes article that we used.

No comments:

Post a Comment