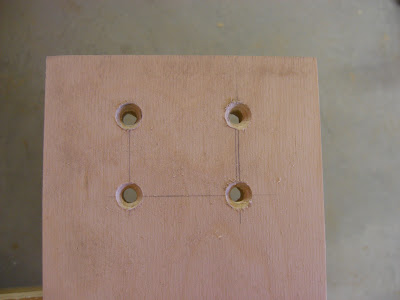

So it was easy to lay out the hole spacing on a piece of Baltic Birch plywood, and drill the holes.

Of course, I had to countersink the screw heads, so that the plywood would sit flush on the shelf.

Even with that huge assortment of screws that I had, I still didn't have four matching ones. So off I went to the local hardware store.

Of course, once I got to the store, I couldn't remember the length I needed, so I bought a few different sizes, just to be sure.

With the right hardware, this part was easy.

And I'm so fussy, of course I had to align all the screw slots.

Here's the motor mounted to the plywood, awaiting the next step - mounting the pulleys.

On the rollers, there is a 5/8" arbor, where I'll mount the top pulley. But first, I had to knock this pin out.

So I grabbed my "go-to" baby ball peen hammer. It doesn't look that small, but here it is, next to a normal sized one.

Then I grabbed a punch, to knock the pin all the way out.

And then mounted the pulley with a set screw.

With a level, I tried to roughly align everything.

Before I could mount the lower pulley to the motor, I realized I needed a piece of keystock for the motor shaft.

Luckily, I had a long piece of it sitting in a drawer.

So I put it in a vice and cut off a small piece of it.

Then filed off the rough edges.

Then filed off the rough edges.

With a little bit of coaxing, the pulley was mounted to the motor shaft.

The next part was easy - place the motor on the shelf below, and slip the belt onto both pulleys.

The only problem - the belt was a little long, making it way too loose on the pulleys.

Do you think I could wait until I had the right sized belt? Hells no, I clamped the motor/plywood down and flipped the switch on for the motor.

And I have to say - watching that motor slowly turn the rollers was a moment of sheer joy. My buddy Dave, the designer of this system, not only included a speed control for this motor control, but he made the motor reversible. It's an incredibly sweet system.

But because the belt was so loose, I didn't try running any clay through the rollers.

Next step - either lowering the shelf to make the belt tighter. Or buying a smaller belt. Hopefully, my next (and final) post about this slab roller retrofit will include a short video to show how great this works.

Stay tuned...

1 comment:

Thanks for posting this. I have recently asked a quesiton about motorizing my slab roller on Clayart. Gay refered me to this post. Can you tell me where to get the motor and the pulley?

Many thanks

May

Post a Comment