Everyone always remarks how life is so different these days - driverless cars, social media politicking, Yelp, Uber and Snapchat; it’s all changing. Even ten years ago, no one could have predicted what would be popular today. So staying flexible in this ever changing society is a must.

(Flexible, get it?)

I certainly didn’t see that I’d be getting a whole bunch of commissioned work from Air BNB hosts - people who open their home as mini bed & breakfast hotels. To be a registered AirBNB host, you have to outfit your home to certain standards, and that’s where I come in. I’ve been working with various homeowners, sprucing up their furniture so that it's more attractive, safer, and durable. On top of that, sprucing up your furnishings adds a cohesive design element to your home.

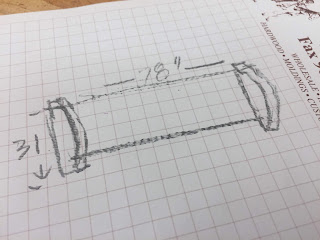

Sometimes the projects that come to me are very vague; this homeowner sketched a headboard that she wanted me to build on a scrap of paper.

I actually prefer to work like this, without firm dimensions that I have to adhere to - so that I have some flexibility when building.

So this started out with a simple sketch, and in this case - they even dropped off some paneling that they had. (Not my choice of building material, but like I said - flexibility is good.)

Their goal was to have a headboard that attached to the wall, with two “bedposts” crating a small alcove for the people in bed. Because there was other furniture in the bedroom that this headboard had to match, they wanted to employ curves in the design of the bedposts.

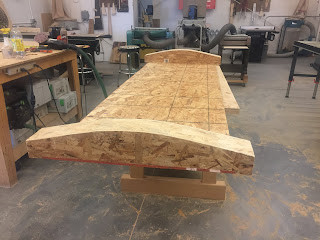

I started with the flat paneling, adding the posts on either end. Building up layer after layer, I was able to create the curve they wanted.

It’s funny how the timing of this project coincided with the AWFS show that was in town; the fine people at Pony/Jorgensen donated a bunch of their new clamps to my shop, and they came in really handy for clamping the boards in place while I marked the cuts I needed to make.

A few years ago, at the 2017 AWFS show, I won a huge package of Senco tools - six nail guns, a compressor, and all the accessories that one would need. These three guns have become workhorses in my shop - the 23 gauge pin nailer, the 18 gauge brad gun, and a stapler. In this case - the stapler was helped me build this headboard effortlessly… working with this type of paneling is all about - glue, staple, and repeat!

The posts are starting to take shape, you can see how I created that subtle curve on the front edge. Like I said - glue, staple, and repeat! This glue bottle took a beating!

After the curved stack was complete, I capped the ends and trimmed everything flush with the router and a flush cut bit.

Here’s the finished headboard, which will be covered in a faux textured stucco to match the rest of the room. It hangs on the wall with Z clips, and despite working with materials that I don’t love, this was a very fun piece to build… no pressure, and freedom to build it however I wanted.

I’ll take that kind of work any day!

3 comments:

I like to see posts about projects, as I love to see your approach on solving the various problems to achieve the final result.

From what I read, the reason you used paneling as the material was because the customer dropped it off in your shop and it was available.

First questions: If you had the latitude to pick your material of choice for a project like this, what would it be? Would another material have made the job easier? Would you have constructed it differently?

Second question: The surface area on the ends of the top three bent panels is very tiny on the ends, as they all meet at a single point. Did you use wedges to increase the surface area for the glue?

That is certainly a cool project. I hope your customer will take a picture of the finished and installed product. It would be good to see how it looks in the room.

Thank you!

If I had my way, I would have made this out of Baltic Birch plywood - stronger and with a smoother surface. The 1/4" BB would be much easier to bend than this OSB panel. That said - the customer is going to apply texture to this piece with a faux stucco, so it really doesn't matter in the end.

Adding enough glue and staples to the ends of this piece, I didn't think there was a need to add wedges to increase the surface area. It's solid, and not going anywhere. But that was a good question!

Post a Comment