Repairs? Sure, I can fix that!

I can't remember another time when there have been more repairs coming into the shop. Chairs, tables, cabinets - you name it, it's probably sitting in my shop.

Maybe it's Spring cleaning, when people look around their homes and decide to tackle furniture projects the they've been ignoring. During the last couple of weeks, it's been almost overwhelming, especially when these repairs add to the growing list of other pieces I'm building.

A friend asked me why I bother with repairs.... so here's a story about why I do them.

Years ago, when my family moved from Los Angeles to Ohio, an aunt of mine purchased a small roll-top desk for me.

But it was missing the drawers.

We tried find someone to make drawers for the desk... it was nearly impossible. These weren't anything special - just some simple boxes to fit into the drawer openings on the desk. (We had the drawer faces, we just needed the drawer boxes.)

Finally, an employee at a local lumberyard agreed to make them. And even though he had a good heart, the drawers he made were really crude - plywood boxes, the sides were nailed together, and the bottoms stapled in place. All in all - just about the WORST drawer construction ever.

I remember how hard it was to find someone to do this simple project, and it stuck with me.

So that's why I do repairs - people need simple woodworking stuff done.

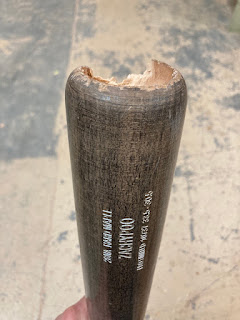

Like the fellow who brought his son's baseball bat into the shop this week.

He'd chipped the end off, and the wasn't allowed to use the bat until it was fixed.

I cut the end off,

taped it to protect the finish,

and routed a curve back into the end on the router table.

It burned a little,

but was easily sanded. All in all, about a 5-minute repair! I didn't even charge him for the repair, it was so simple, and he's a good customer of mine.

Honestly, I don't even remember half of the repairs I do - they come and go so quickly.

But this one is a challenge!

The fellow that brought in these table legs hates their style. He wanted me to turn the lower section into a squared off, taper - and I had to stop and think this one over!

Challenge accepted!

There wasn't any way to simply cut that lower part into a taper. So I decided to make a new lower leg, and attach the two pieces together.

Luckily, the leg still had markings on the end from previous lathe work at the factory where it was made.

So I put it on the lathe, and cut a tenon on the end, first using a parting tool to cut a clean edge.

Once I had a clean cut, I made a 1" tenon for attaching the lower leg.

The size was critical; the digital caliper showed me how close I was. It's just 1/64" too big.

After I shaved it down just a hair more, I cut the leg apart.

I also cut a 1" hole in a piece of scrap, to test it.

Perfect!

I still have to make the four tapered legs next, and attach the two.

Honestly, I don't mind these small jobs - they keep my woodworking skills sharp.

What are you working on?

Did you ever get something that was so poorly made you just couldn’t fix it? Someone once brought me a side table that was previously repaired with nails through broken tenons on the legs, huge globs of glue on the base and the top nailed on with long angled nails every which way.

ReplyDeleteI've turned down a job or two like that!

ReplyDelete