Friends are the spice of life, right?

My buddy Rick is a designer, computer whiz, woodworker, inventor, and one of the nerdiest guys that I know. I say that with a ton of love and respect for him!

The other day, he decided to paint and trick out his shop vac, turning it into a droid. Because.... why not?

Like I said - NERD!

He has so many tools and tricks up his sleeve, but he relied mostly on his 3D printer. And his creativity.

He painted the body of the vacuum with a shellac primer, ordering a couple colors of paint from Home Depot.

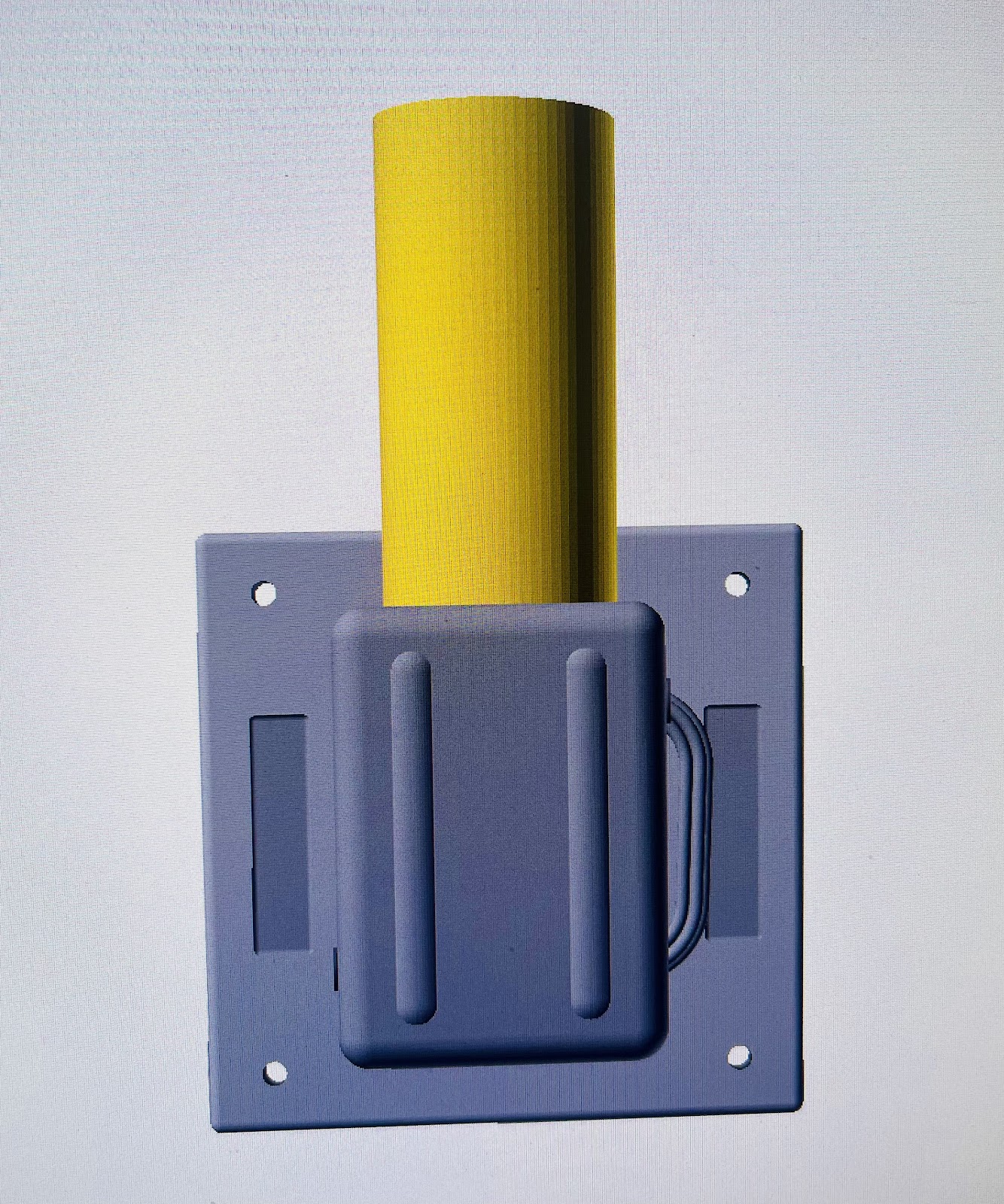

He dug out some semi transparent filament for the buttons and the lights, to make it look more realistic. While he was printing the light panels, he started thinking about the arms, and designed them to hold the end of the hose. The other one will hold the bag of accessories so it’s all together. (Smart design, I love it!)

Again - they are curved on the back for the round body and the yellow pipe can be a hook or hold the end of the hose.

He attached the feet and started applying some detail items. Clamping the robot name plate on.